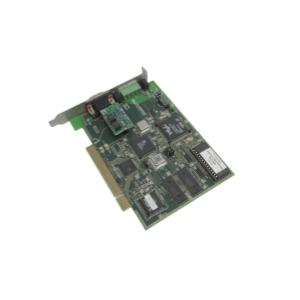

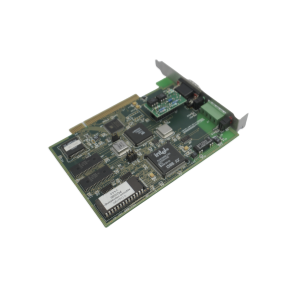

Product Details

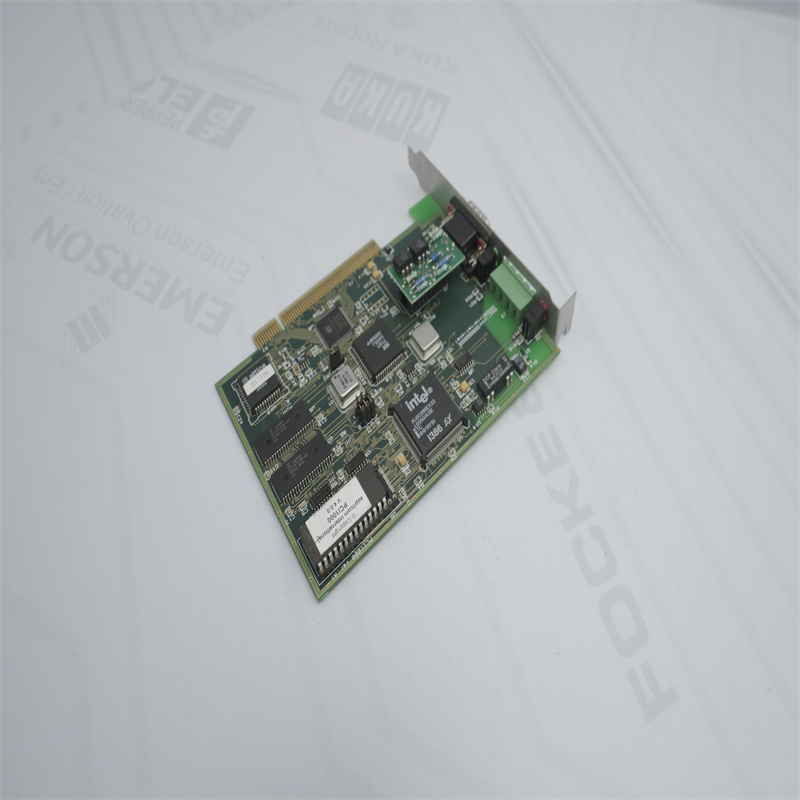

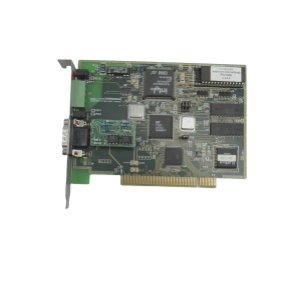

| The O.S. solution allows you to develop and to run your own applications using the applicomIO® API. The O.S. solution contains the different layers of the product (kernel drivers, API and utilities softwares). | |||

APPLICOM-PCI1000 Data sheet | All the supplied layers are already built and can be used without recompilation. This documentation doesn’t include the description of the applicomIO API. | ||

| It allows to send some messages to the board and to wait for answers.The initialisation process (with the player tool) | |||

| Few functions of the applicomIO API (free messaging mode functions only).The second is named "I/O access". It allows getting directly the I/O data in the dual port memory of the board. | |||

|

|

|  |

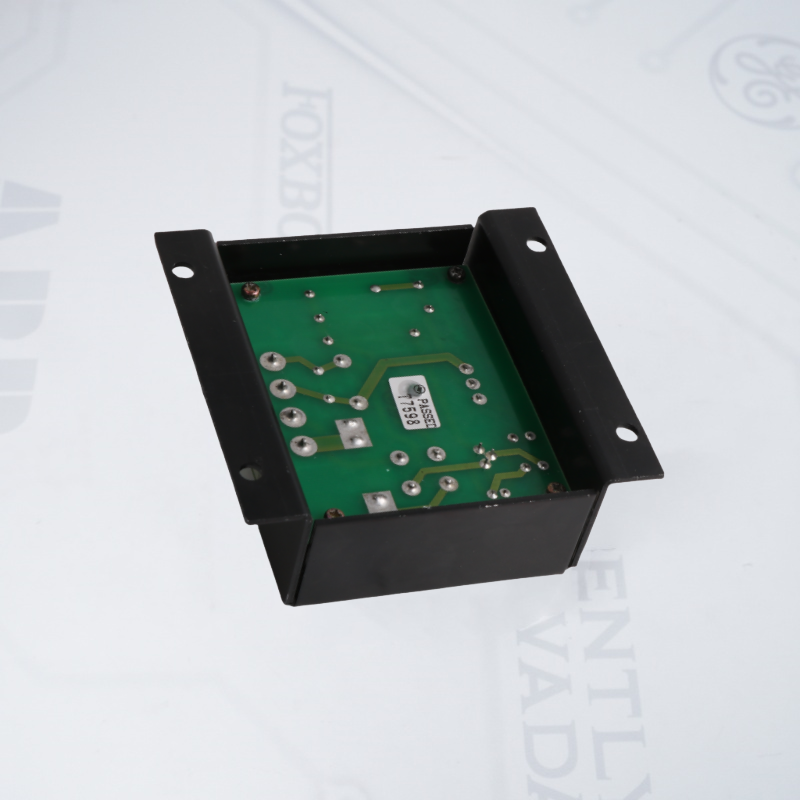

Speed Control Mounting

–40 to +75 °C (–40 to +167 °F). Mount the control in a location with space for adjustment and wiring access. If mounted on the prime mover, do not expose the speed control to sources of radiant heat such as exhaust manifolds or turbochargers. Also choose a protected location so that the control won’t be damaged when moving the prime mover or when equipment is moving near by. Mount the control close to the actuator and battery to meet the wire length requirements. Allow for adequate ventilation. |

The case and mounting plate must be grounded to either the protective earth of the building or, if no protective earth is available, the frame ground of the engine/skid. |

If you want to more details,please contact me without hesitate.Email:sales@sparecenter.com

Speed Control Applications

1

♦ The basic speed control components and connections are shown in Figure 1-1. There are no mechanical drive or hydraulic connections. All input power comes from the battery. The speed control compares the actual speed with the desired speed. It then calculates an error signal and drives the actuator in the increase or decrease fuel direction to correct prime mover speed.

2

♦ Figure 4-1 shows the Electrically Powered Governor in more detail. The speed control is housed in a die-cast aluminum enclosure.

The EPG has two control loops. The speed loop ensures prime mover speed remains constant. The current loop ensures proper drive to the actuator.

3

♦ The speed loop controller has two inputs: the desired speed (speed reference signal) and the actual speed (the speed sensor signal). It compares the two and calculates an error signal which includes dynamic response considerations. Gain and stability adjustments tailor the governor’s response to the requirements of the specific prime mover.

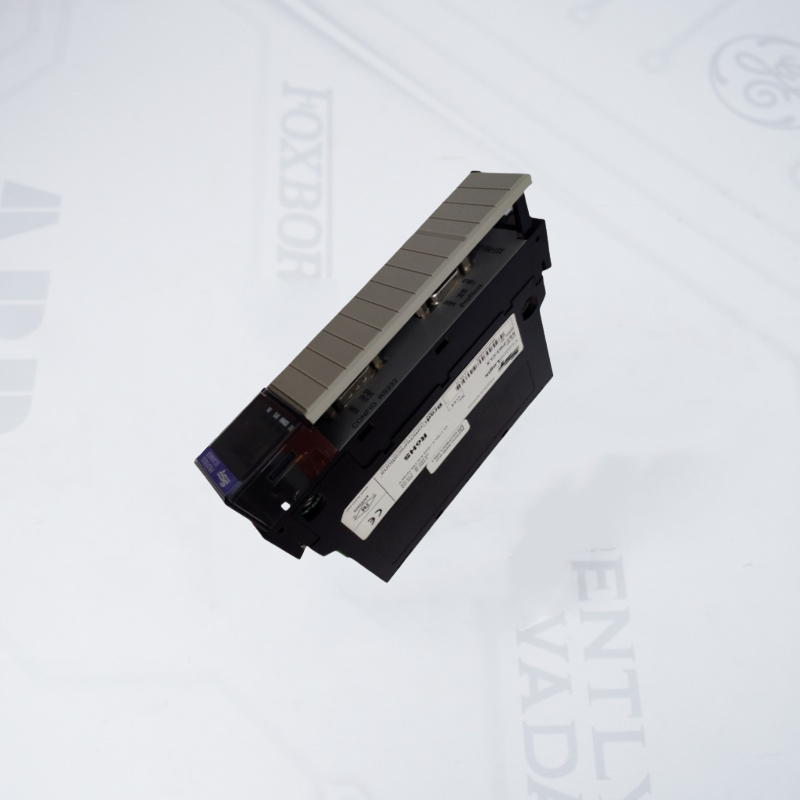

Other Modules

Allen Bradley APPLICOM-PCI1000-CN APPLICOM-PCI1000-CN Allen Bradley1747-KFC15RS-232 Interface Module 288512G1 I/O BOARD Allen Bradley1747-L552Processor Unit Controller 288512G1 I/O BOARD Allen Bradley1756-BA2APPLICOM-PCI1000 Network Interface Cards Allen Bradley1756-CN2/CAPPLICOM-PCI1000 Network Interface Cards Allen BradleyAPPLICOM-PCI1000 Network Interface Cards APPLICOM-PCI1000-CN Allen Bradley1756-IF8ControlLogix APPLICOM-PCI1000 Network Interface Cards Allen Bradley1756-IR6I46-288512G1 I/O WOODWARD Network Interface Cards Allen Bradley1756-L55M12WOODWARD Network Interface Cards Allen Bradley1756-L55M13APPLICOM-PCI1000-CN APPLICOM-PCI1000-CN APPLICOM-PCI1000-CNAPPLICOM-PCI1000-CNAPPLICOM-PCI1000-CN Allen Bradley 1771-OFE2-B Allen Bradley 46-288512G1 WOODWARD Network Interface Cards Allen Bradley1756-L55M14ControlLogix Logix5555 WOODWARD Network Interface Cards Allen Bradley1756-L55M16ControlLogix Logix5555 WOODWARD Network Interface Cards WOODWARD APPLICOM-PCI1000 WOODWARD Network Interface Cards WOODWARD APPLICOM-PCI1000 WOODWARD Network Interface Cards WOODWARD APPLICOM-PCI1000 WOODWARD Network Interface Cards WOODWARD APPLICOM-PCI1000 WOODWARD Network Interface Cards WOODWARD APPLICOM-PCI1000 WOODWARD Network Interface Cards |

Mobile/what's app: +852 6980 6006

Email: sales@sparecenter.com