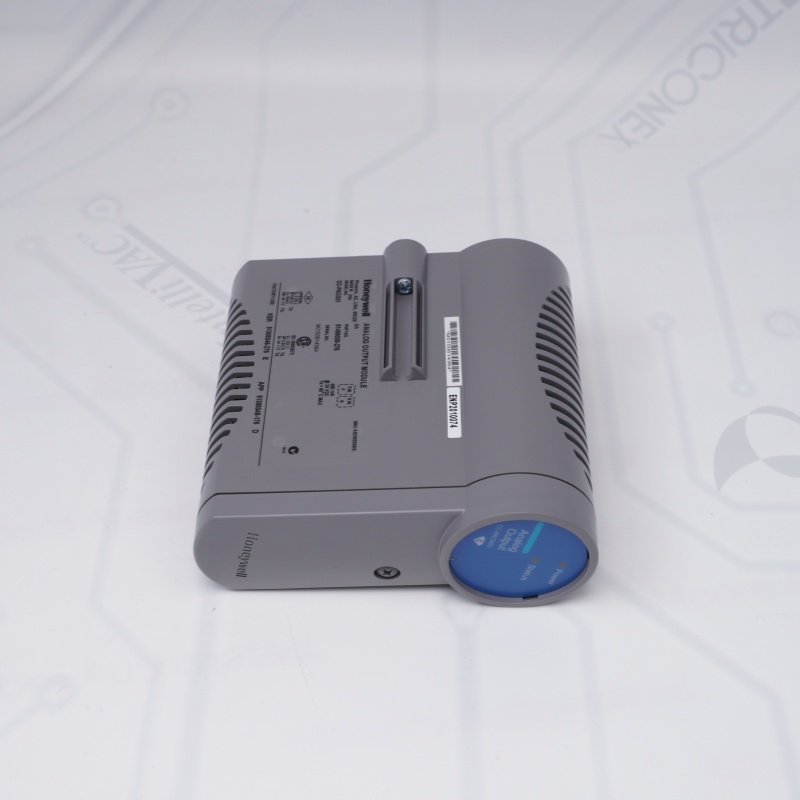

Status Indication

Status Indicator | If the color is | Then the Indication represents |

| PROC RUN/FAULT | Green | The processor module is in the run mode and will begin operation. |

| Blinking Green | The EEPROM memory module (if present) is being programmed. | |

| Red | There is a fault. Recycle power to reset the processor module. | |

| Off | Either program mode of operation, run time error, memory error or a program error. | |

| P/S ACTIVE | Green Off | AC and DC is all right. There has been a power supply fault, overcurrent condition, improper input voltage or the module has been turned off. |

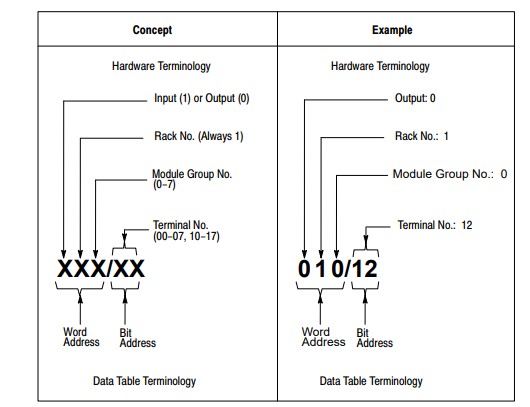

Word Address Equals Memory Bits

|

To calculate the input and output image tables’ areas and how these values

compare with the hardware of your processor. Remember: 1 rack = 8 words You can only have one rack in this system. Therefore: 8 words/rack x 16 bits - 128 I/O Conclusion: The combined amount of usable bits in the input image table and/or the output image table is 128 I/O. |

If you want to more details,please contact me without hesitate.Email:sales@sparecenter.com

Memory Organization

| The data table area is a major part of memory. It is divided into six sections which includes the input and output image tables. (These two areas were described in chapter 2). The processor controls and utilizes words stored in the data table. The input devices coupled with the control logic from your program determines the status of the output devices. Input devices are limit switches, pushbutton switches, pressure switches, etc. Output devices are solenoids, motor starters, alarms, etc. Transfer of input data from input devices and the transfer of output data to output devices occur during I/O scan. If the status of the output instruction changes in the program then the on or off status of the output devices update during the I/O scan to reflect the change. |

| To use the data table, you must understand the following: |

|

|

|

|

|

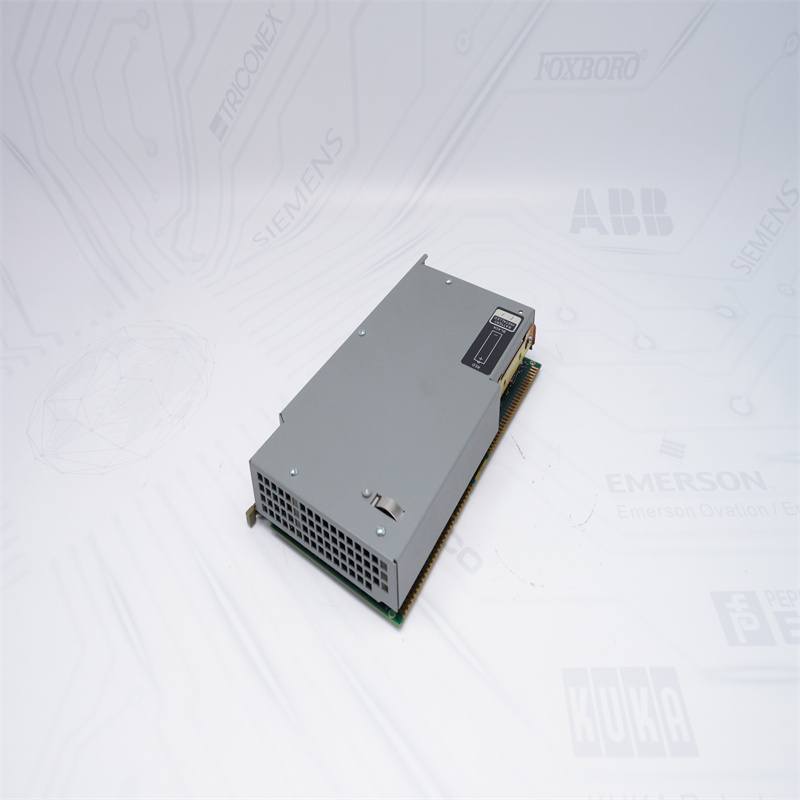

The Functions of The AB 1772-LS

1

Monitoring:

The device provides real-time feedback on system performance and status, allowing for timely adjustments.

2

Communication:

It facilitates data exchange between different automation components, enabling integration within complex systems.

3

Efficiency Optimization:

By providing insights into operations, it aids in improving overall efficiency and performance of automated systems.

Other Modules

Allen Bradley1769-BAAB 1772-LSAB PLC Module Allen Bradley1769-L20AB 1772-LSAB PLC ModuleAB 1772-LS Allen Bradley1769-L31AB 1772-LSAB PLC ModuleAB 1772-LS Allen Bradley1769-OV32TAB 1772-LSAB PLC ModuleAB 1772-LS Allen Bradley1772-LSAB 1772-LSAB PLC ModuleAB 1772-LS AB Power Supply ModulesAB Power Supply ModulesAB Power Supply Modules AB Power Supply ModulesAB Power Supply ModulesAB Power Supply Modules Allen Bradley1772-LWAB Power Supply Modules1772-LS-CNAB 1772-LS Allen Bradley1772-LXAB PLC Module1772-LS-CNAB 1772-LS Allen Bradley1775-GAAB PLC Module1772-LS-CN1772-LS-CN Allen Bradley1775-KAAB PLC Module1772-LS-CN1772-LS-CN Allen Bradley1775-L4AB PLC ModuleAB 17721772-LS-CN Allen Bradley1775-LXAB PLC ModuleAB 17721772-LS-CN Allen Bradley1775-MEA1772-LS-CNAB 17721772-LS-CN Allen Bradley1775-MEDAB 1772AB 17721772-LS-CN Allen Bradley1775-S4AAB 1772AB 17721772-LS-CN Allen Bradley1775-S4BAB 1772AB 17721772-LS-CN1772-LS-CN |

Mobile/what's app: +852 6980 6006

Email: sales@sparecenter.com