Product Specifications

| Brand | Bently Nevada | Bently Nevada 330500 |

| Part No. | 330500 | 330500 |

| Sensitivity | 3.94mV/mm/s (100 mV/in/s) ±5% | Bently Nevada Velomitor Piezo-velocity Sensor |

| Velocity Range | 1270 mm/s (50 in/s) peak | Bently Nevada Vibration Monitor |

| Transverse Sensitivity | Less than 5% of sensitivity | Bently Nevada Vibration Monitoring System |

| Operating Temperature Range | -55°C to 121°C (-67°F to 250°F) | 330500 |

| Weight | 142 grams (5.0 oz), typical | 330500 |

330500 Graphs And Figures And Features

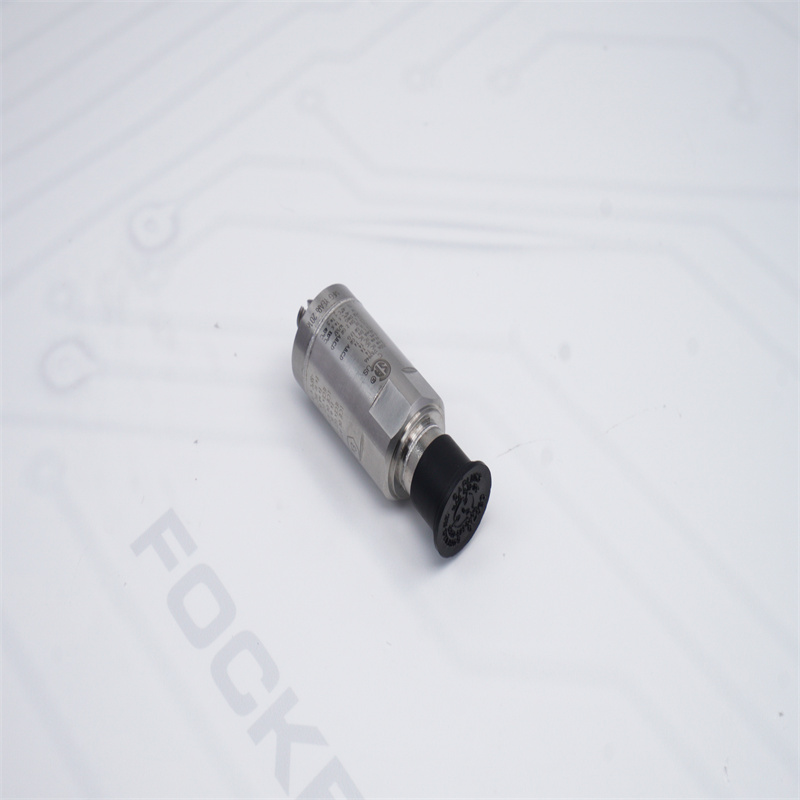

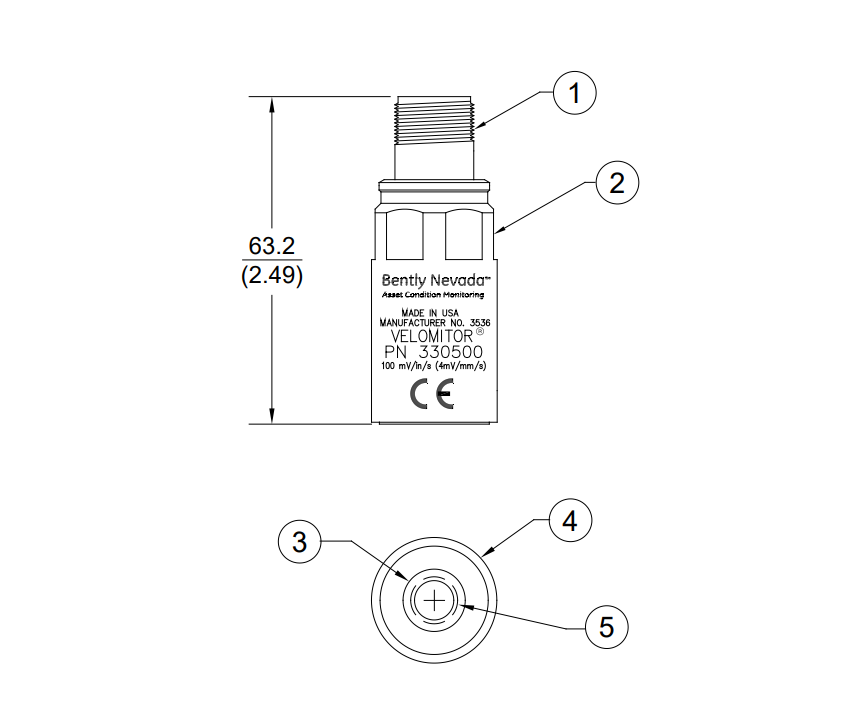

330500 Velomitor Piezo-Velocity Sensor Dimensional Drawing :

1. 2-pin, MIL-C-5015 receptacle

2. 15/16 inch hexagonal

3. 12.7 (0.500) diameter, 0.8 (0.030) deep counterbore

4. 25.3 (0.995) diameter

5. 3/8-24 UNF-2B, 6.4 (0.250) minimum threaded depth, 14.0 (0.550) maximum drill depth

Features:

Incorporates Embedded Electronics

Specialized Piezoelectronic Accelerometers

No Moving Parts

Can be Mounted at Any Angle of Orientation

330500 Bently Nevada Velomitor Piezo-velocity Sensor.Bently Nevada 330500.Bently Nevada Velomitor Piezo-velocity Sensor.

If you want to more,please contact me without hesitate.Email:sales@sparecenter.com

Product Details

Other Technical Data: Mounting Thread Adapter Option : 02 = M8 x 1 Agency Approval Option : 00 = Not required Mounting Torque : 46 kg cm (40 in-lb) max. Connector : 2-pin Mil-C-5015 hermeticallysealed, 316L stainless steel shell. Case Material : 316L stainless steel. Height : 63.2 mm (2.49 in). Diameter : 25.3 mm (0.995 in). Weight : 0.142 Kg Measuring Housings for Transducer Placement If you are measuring a machine housing to determine where to place transducers, consider the types of measurements you want to obtain. Most common machine malfunctions like imbalance or misalignment originate at the rotor and cause a change—usually an increase—in rotor vibration. To obtain high quality data, place the transducer in a location where it can best detect machine vibration through the bearing housing or machine casing. Choose a location, grounding, and shielding that maximizes amplitude and frequency response and lessens data that doesn’t represent actual machine vibration. |

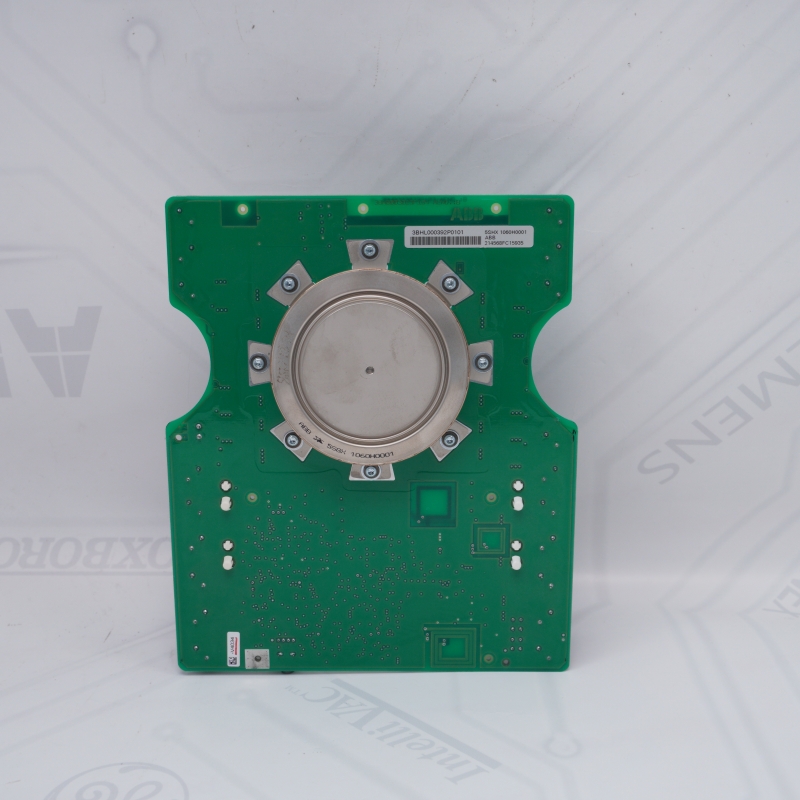

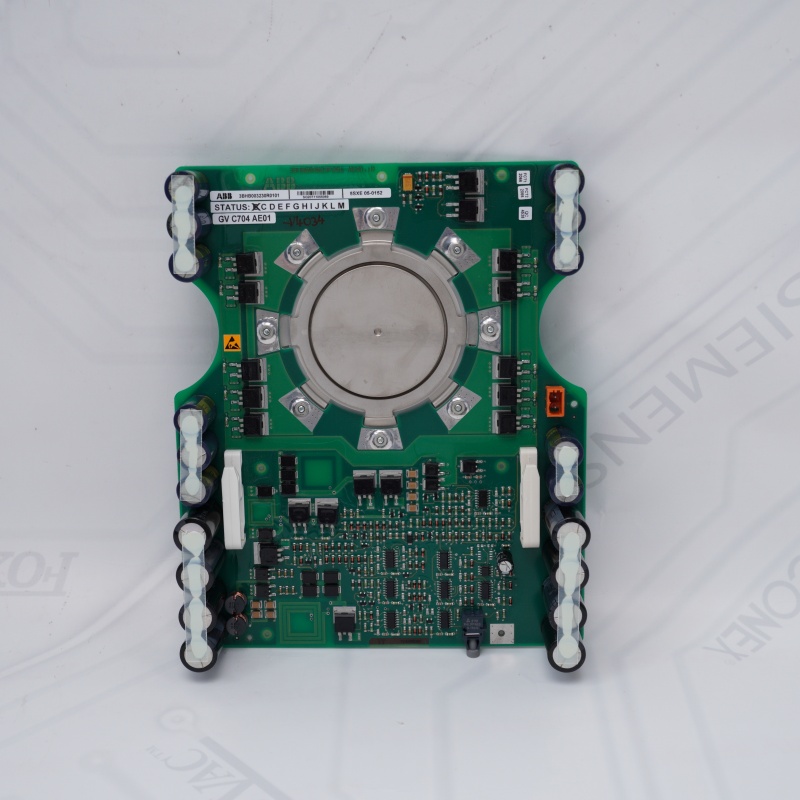

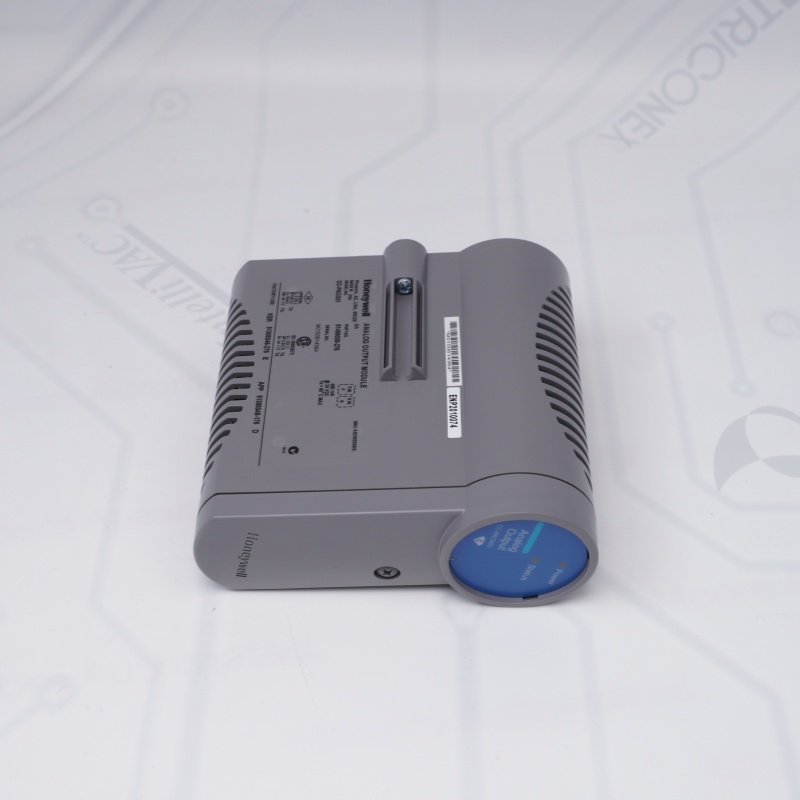

Prodcut Photos

Other Modules

Bently Nevada 3500/93 135799-01 Display Interface Module Bently Nevada3500/93 135785-02Relay System Display Unit Bently Nevada3500/92 136180-01Communication Gateway Module Bently Nevada3500/90Communication Gateway Module Bently Nevada3500/77M 140734-07Pressure Monitor Module Bently Nevada3500/72M 176449-08Recip Rod Position Monitor Bently Nevada 330500 Bently Nevada 330500 Bently Nevada Vibration Monitoring System Bently Nevada3500/65 145988-02Temperature Monitor Bently Nevada3500/64M 176449-05Dynamic Pressure Monitor Bently Nevada3500/62 163179-03Process Variable Monitor Bently Nevada3500/61E 285694-02Temperature Monitor Bently Nevada3500/61 163179-02Temperature Monitor Bently Nevada3500/61 136711-02I/O Module Bently Nevada Vibration Monitor 330500 330500 Bently Nevada Vibration Monitoring System 330500 330500 Bently Nevada3500/60 163179-01Temperature Monitor Bently Nevada3500/60 133811-01Temperature Monitor Bently Nevada 330500 Bently Nevada 330500 330500 330500 Bently Nevada3500/54M 286566-01Overspeed Detection Module Bently Nevada3500/53 133388-01Overspeed Detection Module Bently Nevada3500/50M 286566-02Tachometer Module Bently Nevada3500/50ETachometer Module Bently Nevada3500/50 133388-02Tachometer Module Bently Nevada3500/42E 289837-01Aeroderivitive GT Vibration Monitor Bently Nevada3500/33 149986-0116-Channel Relay Module Bently Nevada3500/22M 288055-01Transient Data Interface Module Bently Nevada3500/22M 138607-01Transient Data Interface |

Mobile/waht's app: +852 6980 6006

Email: sales@sparecenter.com