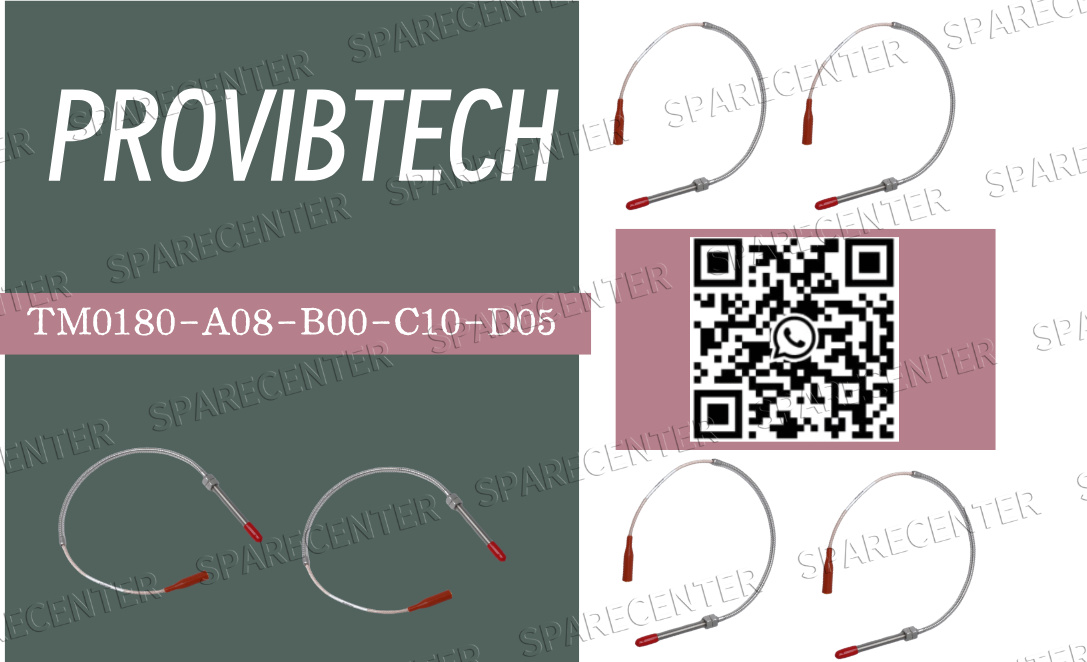

| Introduction In the intricate world of industrial machinery, maintaining optimal performance and preventing catastrophic failures hinges on accurate and reliable condition monitoring. Among the myriad of sensors and systems, the PROVIBTECH TM0180-A08-B00-C10-D05 stands out as a sophisticated solution for displacement measurement and vibration monitoring. This article explores the core features of this advanced proximity probe, detailing its technical specifications and highlighting its pivotal role in ensuring the longevity, safety, and efficiency of critical rotating machinery across various industries through precise condition monitoring. Understanding the Core: Technical Specifications of TM0180-A08-B00-C10-D05 The PROVIBTECH TM0180-A08-B00-C10-D05 is a highly specialized proximity probe, meticulously engineered for non-contact displacement measurement, position, and vibration monitoring. Its alphanumeric designation provides a clear roadmap to its capabilities. The "TM0180" series signifies a high-performance general-purpose proximity probe, designed for robustness and precision in demanding industrial environments. The proximity probe operates on the eddy current principle, generating a high-frequency electromagnetic field around its tip. When a conductive target (like a machine shaft) enters this field, eddy currents are induced, causing a change in the impedance of the probe coil. This change is directly proportional to the gap between the probe tip and the target surface, allowing for highly accurate, non-contact displacement measurement and dynamic motion. Its robust construction ensures reliability and longevity even in harsh industrial settings, vital for continuous condition monitoring. |

The precise capabilities of the PROVIBTECH TM0180-A08-B00-C10-D05 make it an indispensable tool across numerous critical applications, primarily focusing on rotating machinery in sectors such as power generation, oil and gas, petrochemicals, and manufacturing, all benefiting from advanced vibration monitoring.

Turbines (Gas, Steam, Hydro): Used for vibration monitoring of rotor axial and radial displacement, eccentricity, and vibration. Early detection of changes in these parameters through displacement measurement is vital to prevent blade rub, bearing failure, or catastrophic unbalance, ensuring safe and efficient power production.

Compressors: Essential for vibration monitoring of shaft position and vibration on centrifugal and axial compressors. This helps in detecting surge conditions, misalignment, and bearing wear, critical for maintaining gas processing integrity and preventing costly downtime.

Pumps: Applied to large industrial pumps to monitor shaft movement and vibration levels, especially in high-pressure or high-flow applications. This extends bearing life, reduces seal leaks, and ensures continuous fluid transfer, all enabled by the accuracy of this proximity probe.

Motors and Generators: Provides crucial data on shaft runout and vibration, identifying imbalance or misalignment issues before they escalate into significant damage or operational disruptions for rotating machinery.

Conclusion

Vibration Monitoring Vibration Monitoring Vibration Monitoring Vibration Monitoring Exception Operator Round by Exception Industrial automation Industrial automation Industrial automation Industrial automation Industrial automation Industrial automationProximity Probe Proximity Probe Proximity Probe Proximity Probe Proximity Probe Condition Monitoring Condition Monitoring Condition Monitoring Condition Monitoring Condition Monitoring

If you want to more details,please contact me without hesitate.Email:sales@sparecenter.com