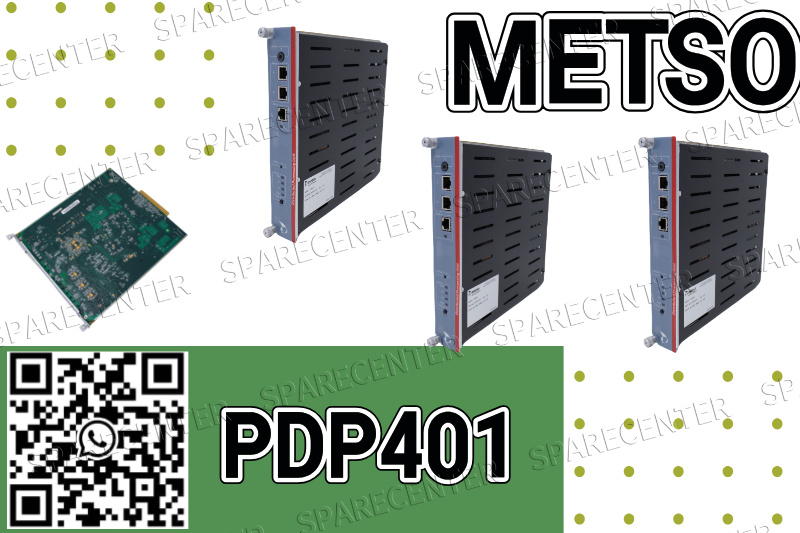

Introduction The METSO PDP401 stands as a cornerstone of modern industrial operations, a robust and intelligent processing unit designed to excel in challenging environments. This article will delve into the critical technical capabilities and transformative impact of the METSO PDP401, highlighting its pivotal role in facilitating advanced distributed control and ensuring exceptional high reliability across various sectors. Its contribution to overall process optimization makes it an indispensable component in today's sophisticated industrial landscapes. Technical Prowess: The METSO PDP401 and its Advanced Capabilities The METSO PDP401 is engineered as a high-performance module, central to Metso's comprehensive distributed control systems. At its core, the PDP401 is built for robust real-time control, capable of executing intricate control algorithms and handling high-speed data acquisition with unparalleled accuracy. This ensures that critical process variables are continuously monitored and adjusted without delay, which is vital for maintaining consistent product quality and operational safety in process control applications. The module typically houses industrial-grade microprocessors specifically optimized for demanding real-time control environments, enhancing its overall high reliability. A significant strength of the METSO PDP401 lies in its seamless integration within Metso's larger distributed control architecture. It leverages proprietary communication protocols to facilitate secure and efficient data exchange across extensive industrial networks. This capability promotes distributed intelligence, allowing local decision-making and significantly reducing latency, a key factor for effective process control. The I/O interface of the METSO PDP401 is highly adaptable, supporting a wide range of analog and digital signals, enabling it to connect with a diverse array of sensors and actuators crucial for comprehensive industrial automation. Furthermore, the physical construction of the METSO PDP401 emphasizes durability and high reliability, designed to withstand extreme conditions, including temperature fluctuations, humidity, and vibrations, thereby guaranteeing a long operational lifespan and minimizing downtime for critical process control systems. |

The robust design and advanced real-time control capabilities of the METSO PDP401 make it an invaluable asset across numerous industrial automation sectors, particularly where continuous and precise process control is essential. It is extensively deployed in pulp and paper mills, managing complex operations like stock preparation, paper machine control, and drying, which directly leads to process optimization in terms of consistent product quality and optimized energy consumption. In the demanding mining and aggregates industry, the METSO PDP401 plays a crucial role in crushing, grinding, and material handling systems within distributed control environments, contributing to increased throughput and substantial reductions in operational costs.

Beyond these core industries, the METSO PDP401 also finds significant application in power generation, chemical processing, and metals production. Its ability to provide stable and accurate process control over critical parameters, combined with its inherent high reliability, yields numerous operational benefits. These include enhanced process stability, leading to superior product quality and reduced waste, and improved operational efficiency through optimized resource utilization – all facets of successful process optimization. The architecture supported by the METSO PDP401 in distributed control systems also streamlines system expansion and simplifies maintenance, offering greater flexibility for future upgrades and troubleshooting, ultimately contributing to a lower total cost of ownership in complex industrial automation setups.

Conclusion