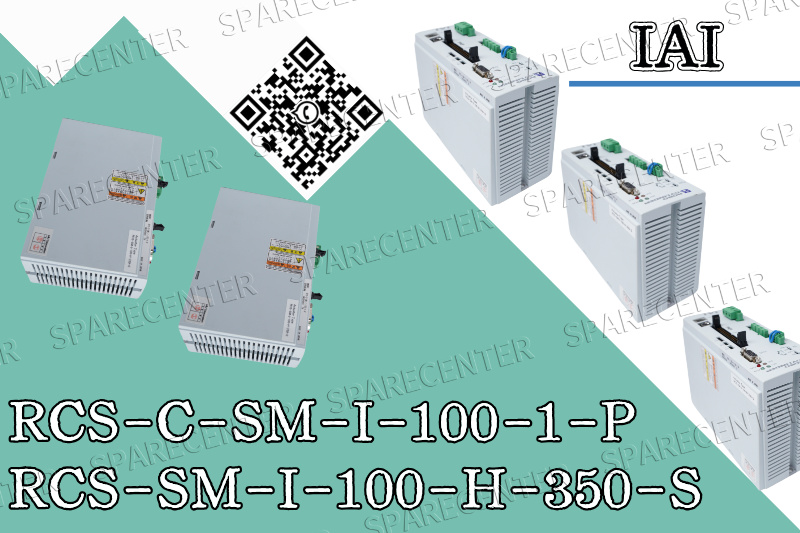

Introduction In the dynamic world of industrial automation, the relentless pursuit of precision motion, unwavering reliability, and optimal efficiency drives innovation. Manufacturers are constantly seeking advanced servo control solutions to streamline operations, minimize downtime, and achieve unparalleled accuracy. At the forefront of this technological revolution stands IAI Corporation, with its groundbreaking IAI RCS-SM-I-100 series. This article delves into two prominent models from this pivotal series – the IAI RCS-C-SM-I-100-1-P and the IAI RCS-SM-I-100-H-350-S – examining their capabilities, diverse applications, and the profound impact they exert on modern industrial automation. These servo control units are not merely components; they represent the intelligent core enabling countless high-performance industrial machines to achieve seamless and precise movements in even the most demanding environments. The Technical Edge: Dissecting the RCS-C-SM-I-100-1-P and RCS-SM-I-100-H-350-S The IAI RCS-SM-I-100 series is celebrated for its integrated design, which ingeniously combines a servo motor and a compact controller into a single, robust unit. This integrated design significantly simplifies wiring, reduces the required installation space, and substantially enhances overall system reliability. Let's examine the specific attributes of the two highlighted servo control models: The IAI RCS-C-SM-I-100-1-P exemplifies a compact and exceptionally versatile servo control. The "C" typically denotes a "Compact" or "Controller Integrated" design, while "SM-I-100" signifies a particular motor and integrated driver series with a 100W output, a testament to its capability for precision motion. The "-1-P" suffix often indicates specific power input or communication protocol variations. This servo control is meticulously engineered for applications demanding precise, repetitive movements, with a strong emphasis on ease of integration and operation.The RCS-C-SM-I-100-1-P's ability to deliver stable, high-speed, and accurate positioning makes it an indispensable component in light to medium-duty industrial automation tasks, significantly contributing to overall efficiency. In contrast, the IAI RCS-SM-I-100-H-350-S represents a variant of the IAI RCS-SM-I-100 series specifically designed for more specialized or demanding scenarios. While sharing the core "SM-I-100" characteristics, the "-H" often points to a "High-speed" or "High-power" capability within the 100W class, or perhaps a more robust construction for handling heavier loads. The "350" could refer to a specific stroke length in linear applications or a higher continuous torque rating, and the "-S" might denote a "Standard" or "Specific" shaft configuration. This particular servo control is frequently employed in applications requiring not only high precision motion but also superior speed capabilities or the capacity to manage larger inertial loads more effectively. Consider applications like faster pick-and-place operations, more robust material handling, or advanced automated inspection systems where rapid, yet precise, movements are absolutely critical. |

The IAI RCS-SM-I-100 series, encompassing models like the RCS-C-SM-I-100-1-P and RCS-SM-I-100-H-350-S, profoundly impacts a wide array of industries due to their consistent delivery of high-performance precision motion control. Their ability to enhance efficiency and reliability is a key differentiator.

In the electronics manufacturing sector, these servo control units are paramount for precise component placement, intricate soldering, and rigorous testing processes, where micron-level accuracy is often a non-negotiable requirement. The compact size of the RCS-C-SM-I-100-1-P is particularly advantageous here, facilitating denser machine designs and improving overall efficiency. The high-speed capabilities of the RCS-SM-I-100-H-350-S are crucial in high-volume production lines, maximizing throughput and accelerating manufacturing cycles.

The medical device manufacturing industry heavily relies on these servo control systems for the intricate assembly of precision instruments, highly accurate dosage systems, and sophisticated diagnostic equipment. The inherent reliability and exceptional precision motion of IAI's servo control systems ensure the consistent quality and safety of these critical products, vital for public health.

Within packaging and logistics, the IAI RCS-SM-I-100 series drives everything from automated bottle filling and capping machines to advanced robotic palletizers and complex sorting systems. Their capacity to execute rapid and precise movements significantly boosts efficiency and reduces the need for manual labor, directly leading to faster delivery times and substantial reductions in operational costs.

Conclusion

IAI RCS-SM-I-100 IAI RCS-SM-I-100 Servo Contro Servo Contro Servo Contro Servo Contro Servo Contro Precision Motion Precision Motion Precision Motion Precision Motion Precision Motion Industrial Automation Industrial Automation Industrial Automation Industrial Automation Industrial Automation Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Efficiency Precision Motion Precision Motion IAI RCS-SM-I-100 IAI RCS-SM-I-100

If you want to more details,please contact me without hesitate.Email:sales@sparecenter.com