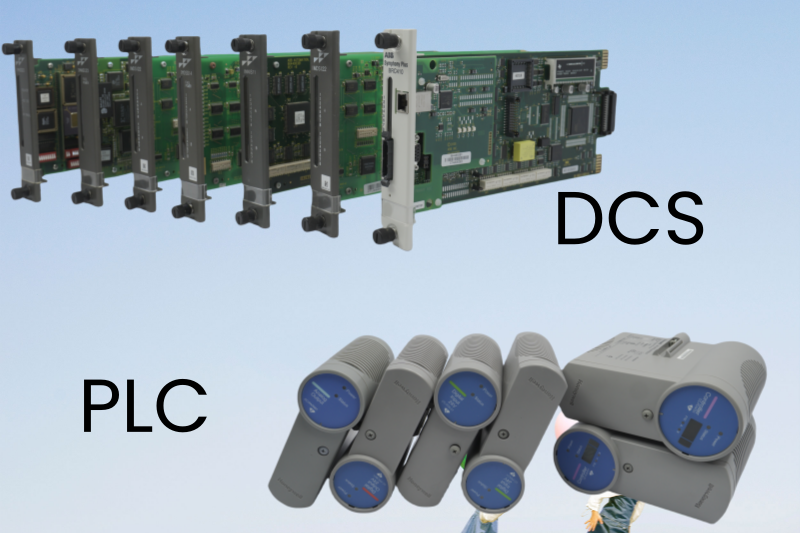

DCS vs. PLC: Understanding the Differences and Applications

Introduction

In the realm of industrial automation, two key technologies stand out for their pivotal roles in controlling and monitoring processes: Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC). Both serve distinct purposes and find applications across various industries, making it crucial to understand their differences, strengths, and ideal use cases. This article delves into the specifics of each technology, comparing their applications, architectures, control capabilities, and scalability, and highlighting their respective advantages and disadvantages.

What is DCS?

A Distributed Control System (DCS) is a specialized control system used predominantly in process industries such as oil and gas, chemical processing, and power generation. It is engineered to manage complex processes that involve multiple control loops and analog signals. DCS architecture typically consists of multiple autonomous controllers distributed throughout a facility or plant. These controllers communicate with each other and a central supervisory system via a high-speed network.

Key Features of DCS

Centralized Monitoring: DCS systems provide a centralized platform for monitoring and controlling all the processes within a plant. This centralization ensures cohesive management and streamlined operations.

High-Speed Network: Communication in DCS systems occurs over a high-speed network, allowing real-time data acquisition and control. This is crucial for maintaining process integrity and operational efficiency.

Advanced Control Capabilities: DCS systems are designed to handle complex control algorithms and advanced process control techniques, which are essential for optimizing process performance and achieving high precision.

Redundancy and Reliability: DCS systems often include redundant controllers and communication paths to ensure high reliability and minimize downtime in critical industrial environments.

What is PLC?

A Programmable Logic Controller (PLC) is a ruggedized digital computer designed to automate electromechanical processes in discrete manufacturing industries. PLCs excel in applications where tasks are repetitive and require precise control over machinery and processes. They are widely deployed in industries such as automotive manufacturing, packaging, and assembly lines, where reliability and real-time performance are critical.

Key Features of PLC

Modular Design: PLCs have a modular design, allowing for easy customization and expansion. This flexibility is particularly beneficial for small to medium-sized automation projects.

Real-Time Control: PLCs are capable of providing real-time control and fast response times, which are essential for discrete manufacturing processes that involve rapid, sequential operations.

Ease of Programming: PLCs are known for their user-friendly programming interfaces, which make it easier for technicians and engineers to develop and modify control programs.

Durability: Designed to withstand harsh industrial environments, PLCs are robust and reliable, ensuring consistent performance even under adverse conditions.

Key Differences

Applications:

DCS: Primarily used in industries where continuous control and monitoring of large-scale operations are essential. Examples include chemical plants, refineries, and power plants. DCS systems are ideal for processes that require meticulous control of numerous variables and where the cost of downtime is high.

PLC: Ideal for discrete manufacturing industries where tasks are discrete and involve sequential control. Common applications include conveyor systems, robotic assembly lines, and material handling. PLCs are well-suited for applications that demand high-speed operations and frequent changes in control logic.

System Architecture:

DCS: Centralized architecture with multiple controllers distributed throughout the plant. Each controller manages specific sections of the process and communicates through a central supervisory system. This distributed nature allows for efficient handling of complex processes and high integration of various control functions.

PLC: Typically operates as a stand-alone unit or a small network of controllers. PLCs are directly connected to sensors, actuators, and other control devices, often organized in a modular fashion. This modularity provides flexibility in system design and makes it easy to expand or reconfigure the system as needed.

Control Capability:

DCS: Optimized for handling complex processes involving analog signals and continuous control loops. DCS systems offer robust capabilities for precise control, data acquisition, and integration with advanced control strategies. They are equipped to manage a high volume of data and provide sophisticated process control.

PLC: Suited for discrete control tasks where logic operations, sequencing, and timing are critical. PLCs excel in executing logic-based operations and managing digital I/O (input/output) signals. They are particularly effective in applications where control tasks are repetitive and straightforward.

Scalability:

DCS: Scalable from small to large systems, capable of managing extensive networks of controllers and devices across a wide area. DCS architectures are designed to accommodate complex industrial processes with high reliability and redundancy. They can seamlessly integrate additional control points and expand as the process grows.

PLC: Modular and scalable, allowing for easy expansion or modification based on specific application requirements. PLC systems are adaptable to various industrial settings and can be integrated into existing automation environments. This scalability makes them suitable for a wide range of applications, from small standalone systems to complex networked installations.

Applications and Use Cases

DCS Applications:

Continuous Process Industries: DCS is extensively used in industries like refining, petrochemicals, and power generation, where continuous control and monitoring are crucial.

High-Integrity Control Systems: Applications requiring high-integrity control systems with built-in redundancy for enhanced reliability benefit significantly from DCS. This includes critical infrastructure where system failure can have severe consequences.

Advanced Control Strategies: Integration with advanced control strategies like optimization algorithms, predictive maintenance, and real-time process monitoring is a key strength of DCS systems.

PLC Applications:

Discrete Manufacturing Operations: PLCs are widely used in automotive assembly lines, packaging, and material handling operations, where tasks are discrete and involve precise control.

Machinery Control: Control of machinery and equipment that require precise timing, sequencing, and logic-based operations is a primary application of PLCs.

Flexible Programming: PLCs offer flexible programming capabilities suitable for a wide range of industrial automation tasks, making them versatile tools in various manufacturing environments.

Advantages and Disadvantages

DCS Advantages:

Superior for Managing Large-Scale Processes: DCS systems excel in managing large-scale, continuous processes with complex control requirements.

High Reliability and Fault Tolerance: The fault-tolerant architecture with redundant controllers and communication pathways ensures high reliability.

Built-in Optimization and Data Acquisition: DCS systems come with built-in features for process optimization, data acquisition, and seamless integration with enterprise-level systems.

DCS Disadvantages:

Higher Initial Investment: The complexity of architecture and specialized nature of applications result in a higher initial investment.

Requires Skilled Engineers: Designing, programming, and maintaining DCS systems require skilled engineers with specialized knowledge.

PLC Advantages:

Cost-Effective for Small to Medium Projects: PLCs offer a cost-effective solution for small to medium-sized automation projects.

Modular Design for Easy Customization: The modular design facilitates easy customization, expansion, and integration into existing control systems.

Accessible Programming Interface: The simple programming interface is accessible to technicians and engineers with basic training.

PLC Disadvantages:

Limited Scalability for Large Systems: PLCsystems may face limitations when scaling up to very large systems with extensive I/O requirements.

Less Efficient with Complex Analog Control: Managing complex analog control is less efficient with PLCs compared to DCS systems.

Conclusion

In summary, choosing between DCS and PLC depends on the specific operational requirements and characteristics of the industrial process. DCS is ideal for industries demanding high reliability, continuous operation, and intricate control strategies. PLCs, on the other hand, excel in discrete manufacturing environments where flexibility, scalability, and precise sequencing are paramount.

Understanding these differences empowers industrial operators, engineers, and decision-makers to make informed choices when implementing automation solutions. By leveraging the strengths of DCS and PLC technologies, industries can optimize efficiency, enhance productivity, and maintain competitiveness in today’s dynamic market landscape.