Product Details

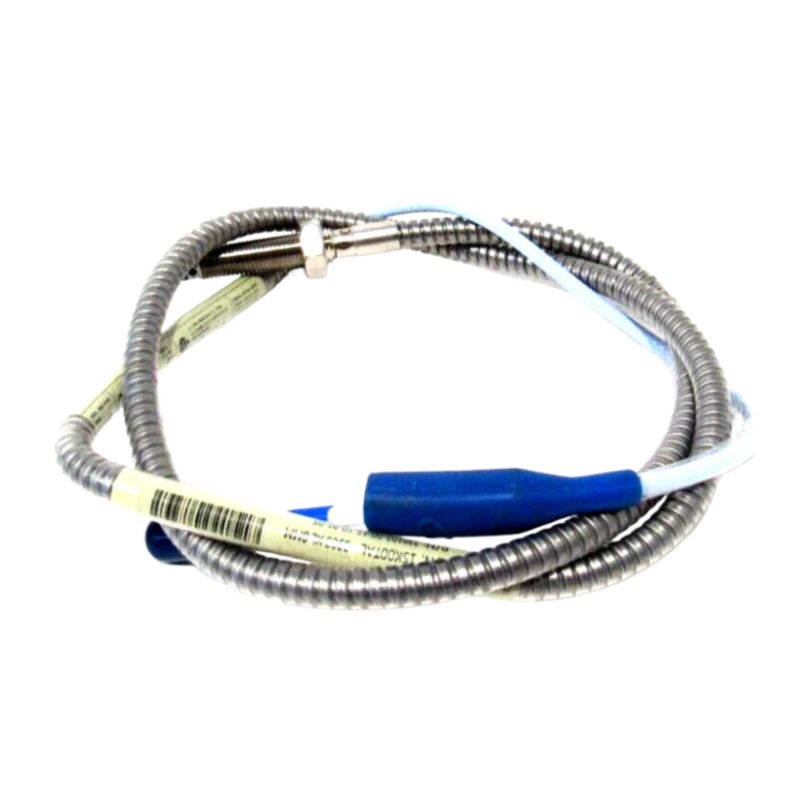

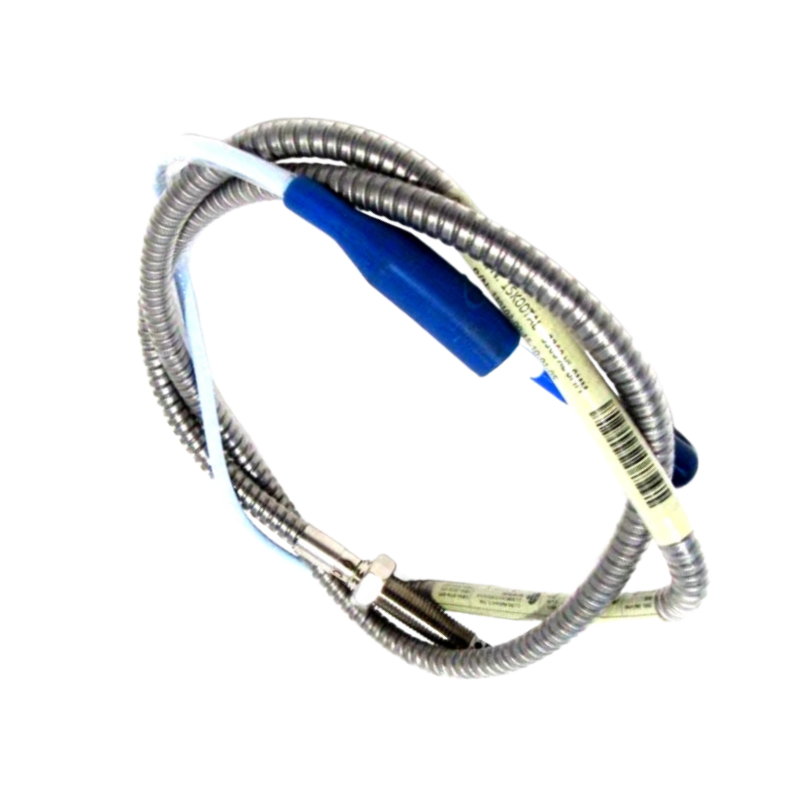

| Introduction In the intricate world of industrial machinery, where the health of a machine is determined by every rotation and vibration, proactive monitoring is not a luxury—it’s a necessity. At the core of many advanced condition monitoring systems lies the proximity probe, a sensor designed to non-invasively measure the movement and position of rotating shafts. This article will focus on a specific, yet crucial, model: the Bently Nevada 330102-00-20-05-01-05. We'll explore what makes this particular proximity probe an indispensable tool for predictive maintenance and how it contributes to ensuring the longevity and reliability of critical machinery. The Technology Behind the Bently Nevada 330102 Proximity Probe The 330102-00-20-05-01-05 is part of the esteemed Bently Nevada 3300 series. At its core, it is an eddy current proximity probe that is essential for accurate vibration monitoring and rotor position analysis. This technology operates on a simple yet highly effective principle: a high-frequency alternating current is passed through a coil at the probe tip, creating a small electromagnetic field. When this field interacts with a conductive material, such as a metal shaft, it induces tiny eddy currents on the surface. As the distance between the proximity probe tip and the shaft changes—due to factors like vibration or a shift in the shaft’s rotor position—the strength of these eddy currents, and consequently the impedance of the probe's coil, changes proportionally. A corresponding monitor converts this impedance change into a voltage signal. This voltage is directly proportional to the physical gap between the probe and the shaft, providing a precise, real-time measurement of the shaft’s behavior for effective condition monitoring and predictive maintenance. |  |

Key Applications and Advantages for Modern Industry

Vibration Monitoring: The probe provides accurate, real-time data on radial and axial shaft vibration. This is invaluable for detecting signs of imbalance, misalignment, or bearing issues long before they lead to a catastrophic failure. This type of vibration monitoring is the cornerstone of proactive maintenance.

Rotor Position and Eccentricity: It continuously measures the static rotor position within its bearings, helping to ensure proper clearance and prevent "rotor rub." The data can also be used to analyze shaft runout and eccentricity, revealing potential shaft bends or other defects, all key to effective condition monitoring.

Thrust Bearing Position: For machinery with thrust bearings, this proximity probe is crucial for monitoring the axial rotor position, which is a direct indicator of thrust bearing wear or failure, thus enabling timely predictive maintenance.

A significant advantage of this specific Bently Nevada probe is its seamless integration with the company's renowned 3500 and 1900 series monitoring systems. This compatibility creates a powerful and cohesive condition monitoring solution, allowing operators to analyze data and make informed decisions about maintenance schedules. The Bently Nevada 330102 Proximity Probe's superior resistance to electromagnetic interference (EMI) and radio frequency interference (RFI) ensures data accuracy and minimizes the occurrence of false alarms, which can be a major issue with less advanced sensors. By providing reliable data for predictive maintenance, the 330102-00-20-05-01-05 helps businesses avoid unscheduled downtime, extend the lifespan of their assets, and significantly reduce operational costs

If you want to more details,please contact me without hesitate.Email:sales@sparecenter.com

Product Images

If you want to more details,please contact me without hesitate.Email:sales@sparecenter.com

Recommend

| R10401HO21 | 1200/90-2 ODC1200902 4321011 | SMARTSCAN 083-002 2PCS |

| FC4A-L03A1 | E82EV551K2C703 E82EV551K2C | 3RF34101BD04 |

| FC4AD40K3 | NORGREN 11400-2G-PG100 | AGS-CPL-101 |

| DS7-340SX016N0-N | ASCO JOUCOMATIC 1027 54326527 | 05.2420.1232.1000 |

| CAA-60/CP159 | SMC EX600-SPN1 | RKH0011/000,6 R911370929 |

| M73203 | SICK DBS60E-BZEZZS150 | BURKERT 00041593 0330 |

| EY-2251-MK.0015 | MINI-UTDE-RJ45 | LC300 702034/8-3100-25 |

| UM30-211111 6037660 | SCHUNK MPG 32 340011 | FAP800-25W-804.5 TO807.5-F90E-4-25C |

| SM8000 | ABB 07EA61 GJV3074351R1 | EGM PME 01 XN404.001.00 |

| 3UG46311AW30 | DFP21B/UOH11B | 6GK73432AH000XA0 |

| MA-TEC TIA-102027 MA-102027 | SICK 1221947 RAY26P-34162530A00 | DANFOSS 027F0246 |

| SOPA-CM4H-R1-HQ6-2P-M12 552133 | EL2014001 | WENGLOR BS40V101 |

| 819-D05-R12-100-10 | HENGSTLER 58872-401 | ARIS 9502-19269-01001 |

Condition Monitoring Condition Monitoring Condition Monitoring Condition Monitoring Predictive Maintenance Predictive Maintenance Predictive Maintenance Proximity Probe Proximity Probe Proximity Probe Bently Nevada 330102 Proximity Probe Bently Nevada 330102 Proximity Probe Bently Nevada 330102 Proximity Probe Bently Nevada Bently Nevada Bently Nevada